404a Operating Pressures (404a pt chart)

The 404A refrigerant is commonly used in commercial refrigeration, providing an efficient, non-ozone-depleting option for low-temperature applications.

Understanding and managing the operating pressures for R-404A is essential to maintain the efficiency, longevity, and performance of refrigeration systems.

In this guide, we will cover every aspect of R-404A operating pressures, troubleshooting practices, and best practices for optimal performance.

What Is R-404A Refrigerant?

R-404A is a blend refrigerant composed primarily of hydrofluorocarbons (HFCs), including R-125, R-143a, and R-134a.

R404A refrigerant plays a crucial role in numerous commercial refrigeration systems. This blend of three hydrofluorocarbons is celebrated for its efficiency and reliability. Importantly, it does not harm the ozone layer, making it an environmentally friendly choice. Imagine R404A as the dependable partner that keeps your products as fresh as a spring morning in the Hill Country.

Known for its stability and efficiency, R-404A is widely used in low and medium-temperature applications, including supermarket refrigeration, ice machines, and refrigerated transport. Its composition is tailored to minimize environmental impact, though it does have a high Global Warming Potential (GWP).

Advantages of R404A in Walk-In Coolers

So, why should you choose R404A? It’s a leading option for maintaining optimal temperatures in walk-in coolers.

Its high efficiency guarantees that your cooler stays at consistent temperatures, significantly lowering energy costs. Furthermore, R404A performs exceptionally well across various temperature ranges, providing versatility for different storage requirements. You could say R404A is the reliable cowboy of cooling—sturdy, efficient, and indispensable.

R404A vs. R134A: Essential Differences

You may have come across R134A as an alternative. While R134A has its benefits, R404A excels in demanding refrigeration applications. The primary distinction lies in their operating pressures; R404A can handle higher pressures, making it better suited for rigorous cooling tasks. Think of it this way: choosing between R134A and R404A is like selecting between a compact car and a robust pickup truck—each serves its purpose, but one is designed for the heavy lifting.

Key Benefits of Using R-404A Refrigerant

- Efficiency in Low Temperatures: Ideal for low-temp refrigeration systems due to its high energy efficiency.

- Non-Ozone-Depleting: Contains no chlorine, which prevents ozone depletion.

- High Compatibility: Works well with both new and retrofitted systems.

R-404A Operating Pressures Overview

Operating pressures for R-404A refrigerant vary with temperature and system conditions. Understanding these pressures is key to achieving optimal performance in different operating environments. Below is an overview of the primary pressures that HVAC technicians should monitor.

Low-Pressure Side (Suction Pressure)

The suction pressure for R-404A generally falls between 10 to 30 psi at normal operating temperatures for low-temperature applications. This pressure is critical to maintaining system efficiency.

Key Points:

- Low suction pressure can indicate issues like restricted airflow or undercharged refrigerant.

- High suction pressure could suggest overcharged refrigerant or blockages in the system.

High-Pressure Side (Discharge Pressure)

The discharge pressure for R-404A ranges from 180 to 220 psi under normal operating conditions. Discharge pressure is influenced by factors like ambient temperature, condenser condition, and system load.

Key Points:

- Elevated discharge pressure often points to dirty condenser coils or inadequate ventilation.

- Low discharge pressure can be a sign of low refrigerant charge or compressor inefficiency.

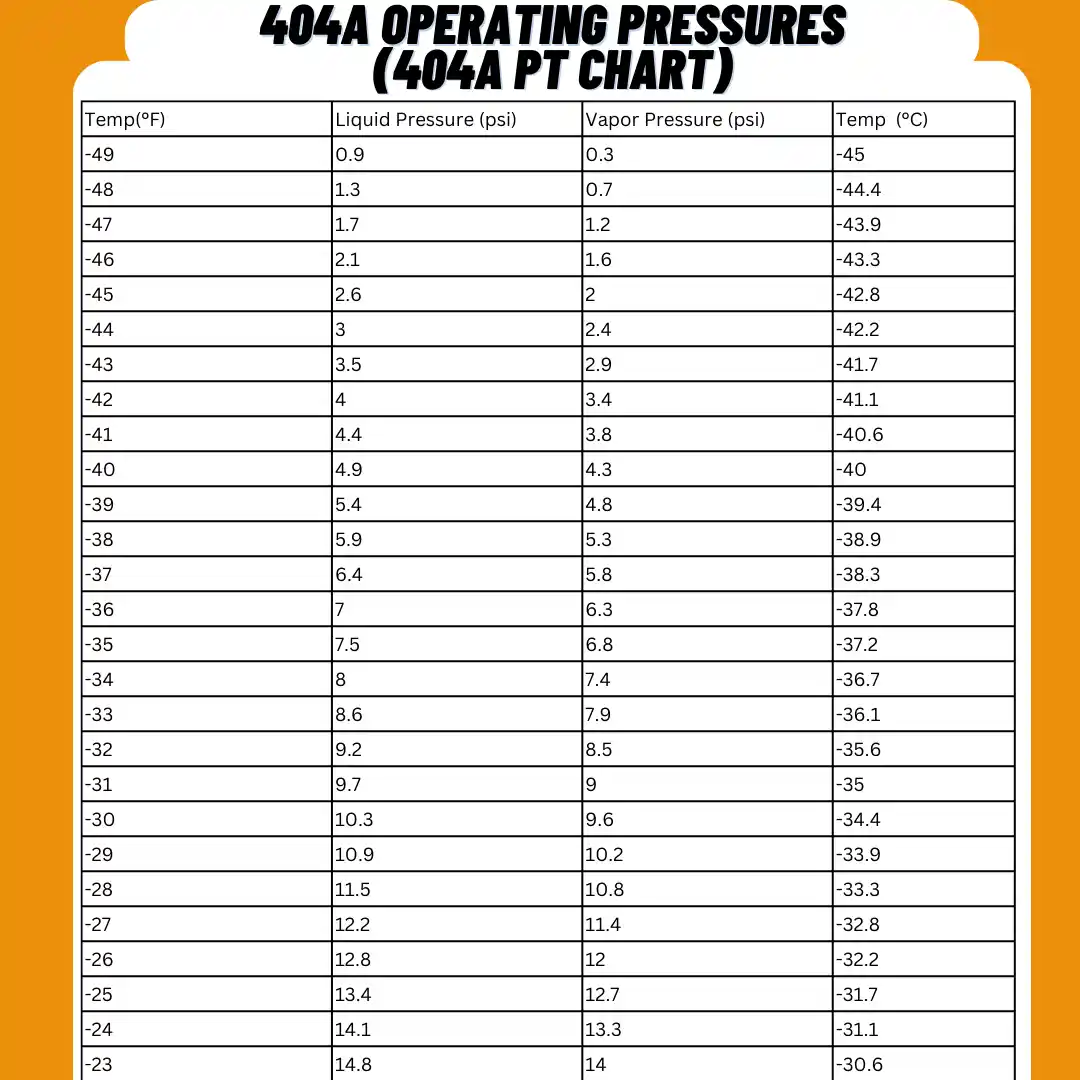

Temperature-to-Pressure Chart for R-404A

To aid technicians, we provide a temperature-to-pressure chart that lists the optimal pressure for various temperatures.

| Temp(°F) | Liquid Pressure (psi) | Vapor Pressure (psi) | Temp (°C) |

|---|---|---|---|

| -49 | 0.9 | 0.3 | -45 |

| -48 | 1.3 | 0.7 | -44.4 |

| -47 | 1.7 | 1.2 | -43.9 |

| -46 | 2.1 | 1.6 | -43.3 |

| -45 | 2.6 | 2 | -42.8 |

| -44 | 3 | 2.4 | -42.2 |

| -43 | 3.5 | 2.9 | -41.7 |

| -42 | 4 | 3.4 | -41.1 |

| -41 | 4.4 | 3.8 | -40.6 |

| -40 | 4.9 | 4.3 | -40 |

| -39 | 5.4 | 4.8 | -39.4 |

| -38 | 5.9 | 5.3 | -38.9 |

| -37 | 6.4 | 5.8 | -38.3 |

| -36 | 7 | 6.3 | -37.8 |

| -35 | 7.5 | 6.8 | -37.2 |

| -34 | 8 | 7.4 | -36.7 |

| -33 | 8.6 | 7.9 | -36.1 |

| -32 | 9.2 | 8.5 | -35.6 |

| -31 | 9.7 | 9 | -35 |

| -30 | 10.3 | 9.6 | -34.4 |

| -29 | 10.9 | 10.2 | -33.9 |

| -28 | 11.5 | 10.8 | -33.3 |

| -27 | 12.2 | 11.4 | -32.8 |

| -26 | 12.8 | 12 | -32.2 |

| -25 | 13.4 | 12.7 | -31.7 |

| -24 | 14.1 | 13.3 | -31.1 |

| -23 | 14.8 | 14 | -30.6 |

| -22 | 15.4 | 14.6 | -30 |

| -21 | 16.1 | 15.3 | -29.4 |

| -20 | 16.8 | 16 | -28.9 |

| -19 | 17.5 | 16.7 | -28.3 |

| -18 | 18.3 | 17.4 | -27.8 |

| -17 | 19 | 18.2 | -27.2 |

| -16 | 19.8 | 18.9 | -26.7 |

| -15 | 20.5 | 19.7 | -26.1 |

| -14 | 21.3 | 20.4 | -25.6 |

| -13 | 22.1 | 21.2 | -25 |

| -12 | 22.9 | 22 | -24.4 |

| -11 | 23.7 | 22.8 | -23.9 |

| 10 | 24.6 | 24.6 | -23.3 |

| -9 | 25.4 | 24.5 | -22.8 |

| -8 | 26.3 | 25.3 | -22.2 |

| -7 | 27.1 | 26.2 | -21.7 |

| -6 | 28 | 27 | -21.1 |

| -5 | 28.9 | 27.9 | -20.6 |

| -4 | 29.8 | 28.8 | -20 |

| -3 | 30.8 | 29.8 | – 19.4 |

| -2 | 31.7 | 30.7 | – 18.9 |

| -1 | 32.7 | 31.6 | -18.3 |

| 0 | 33.7 | 32.6 | -17.8 |

| 1 | 34.7 | 33.6 | -17.2 |

| 2 | 35.7 | 34.6 | – 16.7 |

| 3 | 36.7 | 35.6 | – 25.6 |

| 4 | 37.7 | 36.6 | -15.6 |

| 5 | 38.8 | 37.7 | -15 |

| 6 | 39.8 | 38.7 | -14.4 |

| 7 | 40.9 | 39.8 | -13.9 |

| 8 | 42 | 40.9 | -13.3 |

| 9 | 43.1 | 42 | -12.8 |

| 10 | 44.3 | 43.1 | -12.2 |

| 11 | 45.4 | 44.3 | -11.7 |

| 12 | 46.6 | 45.4 | -11.1 |

| 13 | 47.8 | 46.6 | -10.6 |

| 14 | 49 | 47.8 | -10 |

| 15 | 50.2 | 49 | -9.4 |

| 16 | 51.5 | 50.2 | -8.9 |

| 17 | 52.7 | 51.5 | -8.3 |

| 18 | 54 | 52.7 | -7.8 |

| 19 | 55.3 | 54 | -7.2 |

| 20 | 56.6 | 55.3 | -6.7 |

| 21 | 57.9 | 56.6 | -6.1 |

| 22 | 59.3 | 58 | -5.6 |

| 23 | 60.6 | 59.3 | -5 |

| 24 | 62 | 60.7 | -4.4 |

| 25 | 63.4 | 62.1 | -3.9 |

| 26 | 64.8 | 63.5 | -3.3 |

| 27 | 66.3 | 64.9 | -2.8 |

| 28 | 67.8 | 66.4 | -2.2 |

| 29 | 69.2 | 67.8 | -1.7 |

| 30 | 70.7 | 69.3 | -1,1 |

| 31 | 72.3 | 70.8 | -0.6 |

| 32 | 73.8 | 72.4 | 0 |

| 33 | 75.4 | 73.9 | 0.6 |

| 34 | 77 | 75.5 | 1.1 |

| 35 | 78.6 | 77.1 | 1.7 |

| 36 | 80.2 | 78.7 | 2.2 |

| 37 | 81,8 | 80.3 | 2.8 |

| 38 | 83.5 | 82 | 3.3 |

| 39 | 85.2 | 83.7 | 3.9 |

| 40 | 86.9 | 85.4 | 4.4 |

| 41 | 88.6 | 87.1 | 5 |

| 42 | 90.4 | 88.8 | 5.6 |

| 43 | 92.2 | 90.6 | 6.1 |

| 44 | 94 | 92.4 | 6.7 |

| 45 | 95.8 | 94.2 | 7.2 |

| 46 | 97.6 | 96 | 7.8 |

| 47 | 99.5 | 97.9 | 8,3 |

| 48 | 101.4 | 99.8 | 8.9 |

| 49 | 103.3 | 101.7 | 9.4 |

| 50 | 105.3 | 103.6 | 10 |

| 51 | 107.2 | 105.6 | 10.6 |

| 52 | 109.2 | 107.6 | 11.1 |

| 53 | 11.2 | 109.6 | 11.7 |

| 54 | 113.3 | 111.6 | 12.2 |

| 55 | 115.3 | 113.6 | 12.8 |

| 56 | 117.4 | 115.7 | 13.3 |

| 57 | 119.5 | 117.8 | 13.9 |

| 58 | 121.7 | 119.9 | 14.4 |

| 59 | 123.8 | 122.1 | 15 |

| 60 | 126 | 124.2 | 15.6 |

| 61 | 128.2 | 126.4 | 16.1 |

| 62 | 130.5 | 128.7 | 16.7 |

| 63 | 132.7 | 130.9 | 17.2 |

| 64 | 135 | 133.2 | 17.8 |

| 65 | 137.3 | 135.5 | 18.3 |

| 66 | 139.7 | 137.8 | 18,9 |

| 67 | 142 | 140.2 | 19.4 |

| 68 | 144.4 | 142.6 | 20 |

| 69 | 146.9 | 145 | 20.6 |

| 70 | 149.3 | 147.4 | 21.1 |

| 71 | 151.8 | 149.9 | 21.7 |

| 72 | 154.3 | 152.4 | 22.2 |

| 73 | 156.8 | 154.9 | 22.8 |

| 74 | 159.4 | 157.5 | 23.3 |

| 75 | 162 | 160.1 | 23.9 |

| 76 | 164.6 | 162.7 | 24.4 |

| 77 | 167.3 | 165.3 | 25 |

| 78 | 170 | 168 | 25.6 |

| 79 | 172.7 | 170.7 | 26.1 |

| 80 | 175.4 | 173.4 | 26.7 |

| 81 | 178.2 | 176.2 | 27.2 |

| 82 | 181 | 179 | 27.8 |

| 83 | 183.8 | 181.8 | 28.3 |

| 84 | 186.7 | 184.7 | 28.9 |

| 85 | 189.5 | 187.5 | 29.4 |

| 86 | 192.5 | 190.4 | 30 |

| 87 | 195.4 | 193.4 | 30.6 |

| 88 | 198.4 | 196.4 | 31.1 |

| 89 | 201.4 | 199.4 | 31.7 |

| 90 | 204.5 | 202.4 | 32.2 |

| 91 | 207.6 | 205.5 | 32.8 |

| 92 | 210.7 | 208.6 | 33.3 |

| 93 | 213.8 | 211.7 | 33.9 |

| 94 | 217 | 214.9 | 34.4 |

| 95 | 220.2 | 218.1 | 35 |

| 96 | 223.4 | 221.4 | 35.6 |

| 97 | 226.7 | 224.6 | 36.1 |

| 98 | 230 | 227.9 | 36.7 |

| 99 | 233.4 | 231 | 37.2 |

| 100 | 236.8 | 234.6 | 37.8 |

| 101 | 240.2 | 238.1 | 38.3 |

| 102 | 243.6 | 241.5 | 38.9 |

| 103 | 247.1 | 245 | 39.4 |

| 104 | 250.6 | 248.5 | 40 |

| 105 | 254.2 | 252.1 | 40.5 |

| 106 | 257.8 | 255.6 | 41.1 |

| 107 | 261.4 | 259 .3 | 41.7 |

| 108 | 265.1 | 262.9 | 42.2 |

| 109 | 268.8 | 266.6 | 42.8 |

| 110 | 272.5 | 270.4 | 43.3 |

| 111 | 276.3 | 274.1 | 43.9 |

| 112 | 280.1 | 278 | 44.4 |

| 113 | 284 | 281.8 | 45 |

| 114 | 287.9 | 285.7 | 45.6 |

| 115 | 291.8 | 289.6 | 46.1 |

| 116 | 295.8 | 293.6 | 46.7 |

| 117 | 299.8 | 297.6 | 47.2 |

| 118 | 303.8 | 301.7 | 47.8 |

| 119 | 307.9 | 305.8 | 48.3 |

| 120 | 312.1 | 309.9 | 48.9 |

| 121 | 119.1 | 3141 | 494 |

| 122 | 320.4 | 318.3 | 50 |

| 123 | 324.7 | 322.5 | 50.6 |

| 124 | 329 | 326.8 | 51.1 |

| 125 | 333.3 | 331.2 | 51.7 |

| 126 | 337.7 | 335.6 | 52.2 |

| 127 | 342.1 | 340 | 52.8 |

| 128 | 346.6 | 344.4 | 53.3 |

| 129 | 351.1 | 349 | 53.9 |

| 130 | 355.7 | 353.5 | 54.4 |

| 131 | 360.2 | 35.1 | 55 |

| 132 | 364.9 | 362.8 | 55.6 |

| 133 | 369.6 | 367.5 | 56.1 |

| 134 | 374.3 | 372.2 | 56.7 |

| 135 | 379.1 | 377 | 57.2 |

| 136 | 383.9 | 381.9 | 57.8 |

| 137 | 388.8 | 386.8 | 58.3 |

| 138 | 393.7 | 391.7 | 58.9 |

| 139 | 398.7 | 396.7 | 59.4 |

| 140 | 403.7 | 401.7 | 60 |

| 141 | 408.8 | 406.8 | 60.6 |

| 142 | 413.9 | 412 | 61.1 |

| 143 | 419.1 | 417.1 | 61.7 |

| 144 | 424.3 | 422.4 | 62.2 |

| 145 | 429.6 | 427.7 | 62.8 |

| 146 | 434.9 | 433.1 | 63.3 |

| 147 | 440.3 | 438.5 | 63.9 |

| 148 | 445.8 | 443.9 | 64.4 |

| 149 | 451.3 | 449.5 | 65 |

| 150 | 456.8 | 455.1 | 65.6 |

Common Causes of Pressure Imbalances in R-404A Systems

System issues often result from imbalances in operating pressures. Here are the most common causes and how to address them:

1. Refrigerant Overcharge or Undercharge

An incorrect refrigerant charge directly affects both suction and discharge pressures. Overcharging increases discharge pressure, while undercharging reduces suction pressure.

- Solution: Measure the refrigerant levels using the temperature-to-pressure chart and adjust as needed.

2. Airflow Restrictions

Restrictions in the airflow, often due to clogged filters or dirty coils, reduce efficiency and alter pressure readings.

- Solution: Regularly clean filters and condenser coils to ensure optimal airflow.

3. Compressor Issues

A malfunctioning compressor can result in abnormal pressure readings. For example, worn-out components may lead to low discharge pressures.

- Solution: Inspect compressor components and replace or repair faulty parts as needed.

4. Leaks in the Refrigerant Lines

Leaks cause gradual pressure reduction on both the low and high sides of the system.

- Solution: Use a leak detector to locate leaks and repair or replace affected sections.

Step-by-Step Guide to Charging R-404A Refrigerant

Properly charging R-404A refrigerant is critical to maintain optimal operating pressures. Follow these steps for accurate charging:

Step 1: Recover and Evacuate

- Recover any existing refrigerant using approved equipment.

- Evacuate the system to remove air and moisture, ensuring a clean environment.

Step 2: Connect Manifold Gauges

- Attach the low-pressure side gauge to the suction line.

- Connect the high-pressure gauge to the discharge line.

- Set up the refrigerant cylinder with a charging scale.

Step 3: Charge in Liquid Form

- Open the valve to release R-404A in liquid form.

- Monitor both suction and discharge pressures as the refrigerant flows.

- Adjust the charge to align with optimal values in the temperature-to-pressure chart.

Best Practices for Maintaining R-404A Refrigerant Systems

Regular Monitoring

Regular pressure checks help identify issues early, allowing for preventive maintenance. Recording pressure readings over time can provide valuable insights into system performance.

Avoid Overheating

Overheating can cause the compressor to overwork, resulting in elevated discharge pressures. Keep systems well-ventilated and monitor temperatures.

System Leak Prevention

Since R-404A systems are prone to leaks over time, regular leak detection is vital to prevent pressure imbalances and system inefficiencies.

Troubleshooting Guide for R-404A Refrigerant Systems

Common Issues and Solutions

- Low Suction Pressure

- Cause: Airflow restriction, low refrigerant charge.

- Solution: Check for blocked filters and verify refrigerant levels.

- High Discharge Pressure

- Cause: Overcharge, blocked condenser.

- Solution: Clean condenser coils and ensure proper ventilation.

- Temperature Fluctuations

- Cause: Inconsistent refrigerant levels or leaks.

- Solution: Perform a leak test and add refrigerant as needed.

Frequently Asked Questions

What Should R-404A Operating Pressures Be?

Optimal pressures for R-404A refrigerant depend on the temperature and application. Typically:

Suction Pressure: 10-30 psi

Discharge Pressure: 180-220 psi

Why Is My R-404A System Running at High Discharge Pressure?

High discharge pressure can indicate dirty condenser coils, inadequate airflow, or an overcharge of refrigerant. Ensuring clean coils and balanced refrigerant levels can alleviate this issue.

How Can I Prevent Pressure Imbalances?

Regular maintenance, such as cleaning filters and coils, monitoring refrigerant levels, and checking for leaks, helps maintain balanced pressures.

What should the pressures be for a 404A walk-in cooler?

If you’re wondering about the proper pressures for your 404A walk-in cooler, think of it like tuning a guitar—each pressure setting is essential for optimal performance! In the Houston climate, aim for a suction pressure of around 10-30 psi. This helps maintain the cool environment without freezing everything solid.

What is the running pressure of R404A?

Running pressure is key for smooth operation. For R404A refrigerant in the warm Houston summers, your head pressure should typically range from 180-200 psi. Think of it as the perfect balance—just like enjoying sweet tea at a barbecue!

What are the pressure control settings for 404A?

Consider your cooler as a dance floor—it needs the right music to keep the atmosphere just right. For 404A systems, set your high head pressure around 200 psi, and maintain a low suction pressure between 10-30 psi. This balance helps optimize energy use and keeps the internal temperature steady.

What causes high head pressure in a 404A system?

High head pressure can arise suddenly, much like a surprise summer storm in Houston! Common causes include dirty condenser coils or incorrect refrigerant charge. Regular maintenance checks can help catch these issues before they escalate into bigger problems.

What’s the deal with suction pressure on a 404A?

Suction pressure is like the cooling system’s way of breathing—it needs to be just right. For a 404A walk-in freezer, the ideal suction pressure should generally be between 10 and 30 psi. If your freezer isn’t reaching the desired temperature, check the suction line or pressure control settings for any irregularities.

Why is my freezer running with high head pressure?

High head pressure in Houston can feel like those sweltering August days! This often indicates a clog or misalignment in the system. Start troubleshooting by inspecting the filters, checking the evaporator coil, and verifying the ambient temperature controls. Keeping everything in order will help maintain a cooler environment.

I’m Alan William’s, the founder of SmartHeatSolution.com. I am from California, USA, I’m passionate about innovative heating technologies and their impact on our homes and businesses. With a background in electrican and home repair , I aim to make smart, energy-efficient heating accessible to everyone. When I’m not writing, I’m likely interested in all the thermostat brands and their new technnology. Thanks for stopping by!